MicroSys Electronics adapts NXP® processors for real-time critical industries.

To provide powerful software, the embedded systems manufacturer has entered into a strategic partnership with Cetitec. Ina Schindler, CEO of MicroSys, and Dr. Michael Back, CEO of Cetitec, explain the advantages for customers in this interview.

Dr. Back, how did the partnership between MicroSys and Cetitec come about?

Dr. Michael Back, Cetitec: The partnership began during a joint visit to the Automotive Ethernet Congress in Munich. We quickly realized that our companies complement each other perfectly—MicroSys provides the advanced hardware, and we deliver the software tailored for hard real-time applications. Additionally, both companies are NXP® Gold Partners. Through our close collaboration, we enable optimal use of NXP® SoCs to offer customers innovative and future-proof solutions.

What strengths does Cetitec bring to support MicroSys in application development?

Dr. Michael Back: We’re a leading global provider in the field of fieldbus system connectivity and develop software solutions that serve as central communication interfaces in the automotive industry. As a subsidiary of Porsche, we have deep expertise in connected vehicle architectures. Our collaboration with MicroSys allows us to bring new technologies to market maturity quickly and efficiently. Together, we adapt NXP® automotive processors for applications in markets with high real-time requirements, such as rail, aerospace, mobile machinery, medical technology, and automation.

Ms. Schindler, what advantages does the partnership offer MicroSys customers?

Ina Schindler, MicroSys: Through our collaboration with Cetitec and our shared NXP® partnership, we can implement innovative projects with a high degree of integration for our customers. Especially for automotive clients, it’s a perfect match. Together, we adapt NXP® automotive processors for applications like mobile construction machinery—we call it “Beyond Automotive.” Cetitec provides its extensive software know-how, and in return, we support Cetitec with our innovative hardware solutions.

Can you give a specific example?

Ina Schindler: We are currently working on a research project that optimizes the NXP® S32Z2 processor for use in drones. As part of the “BayCHAMP” project, Cetitec, MicroSys, Tech S.A.T., and AEE Aircraft Electronic Engineering are developing a flight attitude control system that improves drone stability and control precision. These developments have great potential, especially in the agricultural sector, where drones are playing an increasingly important role.

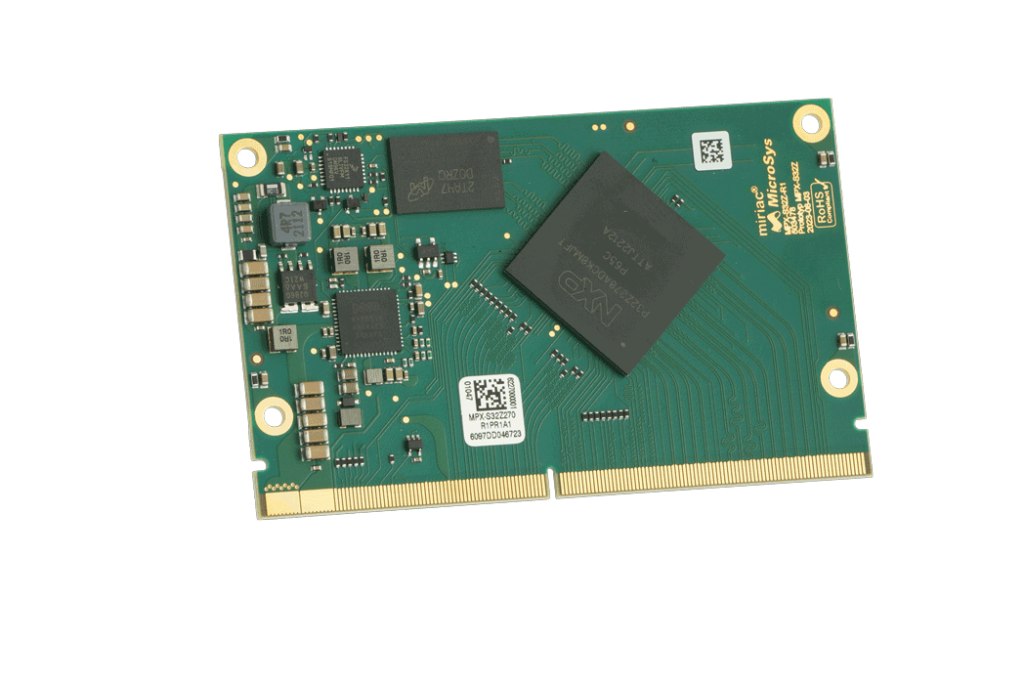

MicroSys recently developed a new module, the miriac® MPX-S32Z2. What are its technical highlights?

Ina Schindler: The miriac® MPX-S32Z2 System-on-Module (SoM) is based on NXP’s S32Z2 CPU with eight Arm® Cortex®-R52 split-lock cores. It also includes a Cortex®-M33 lockstep core with Arm® TrustZone architecture and advanced safety features like memory protection. This CPU enables hard real-time processing and, with an integrated DSP, machine learning capabilities with up to 25 GigaFLOPS. The platform supports AI-powered algorithms for driver assistance systems, autonomous functions, or predictive maintenance.

The module is also very compact, measuring only 82 x 50 mm—ideal for tight spaces found in vehicle architectures. It enables integration and networking of prototypes and axle carriers in automotive applications. Existing platforms can be expanded with new subsystems, hybrid drives, or infotainment systems while simulating environments with future technologies.

What advantages does the module’s CPU offer from Cetitec’s point of view?

Dr. Michael Back: A unique feature of the processor is its dedicated accelerators for safety processing and network communication, known at NXP® as FlexLLCE (Low-Latency Communication Engine) and PFE (Packet Forwarding Engine). These specialized engines allow the CPU to efficiently handle domain and zone control tasks in vehicle architectures. Processing happens with minimal latency, significantly accelerating safety-critical functions such as ECU communication and real-time data handling in vehicle gateways. While often described as hardware acceleration, the performance is actually driven by tailored firmware optimized for the architecture.

The architecture is also highly scalable, allowing developers to implement different operating systems on the cores. In addition to QNX for high-performance control, AUTOSAR OS can be used for resource-efficient real-time processing. Parallel use of multiple operating systems allows each software component to be run in the most optimal environment.

What are the safety and security requirements, and how does the CPU support them?

Dr. Michael Back: To meet stringent functional safety and cybersecurity standards, the S32Z2 processor includes a dedicated Hardware Security Engine (HSE) that ensures secure booting of authenticated firmware only. The secure boot chain protects the module against tampered updates or cyberattacks—especially important in vehicles receiving over-the-air (OTA) updates. Only signed and verified firmware can be installed.

A dedicated microcontroller also monitors voltage levels, protecting the system against unexpected power fluctuations or faulty supplies. This function increases reliability in safety-critical applications and supports ISO 26262 compliance.

Ms. Schindler, comprehensive connectivity is becoming increasingly important in modern vehicle architectures—keyword: Car-to-X communication. How does the module meet these demands?

Ina Schindler: To meet the highest demands for connectivity in cars or construction machinery, the module offers dual Gigabit Ethernet, 16 CAN, and three I3C interfaces. It also supports Zipwire, FlexRay, LIN, and Aurora—covering both traditional and modern communication architectures and enabling efficient integration with existing ECUs and sensors.

While CAN remains widely used for classic ECUs and sensors, modern high-speed bus systems like FlexRay and Ethernet-based protocols are gaining ground. Aurora, a high-speed serial protocol, enables low-latency transmission of high-frequency data streams between FPGAs, processors, or accelerators. The I3C support allows efficient connection of modern sensors for ADAS and environmental perception systems.

The CPU is only one side of the equation—what about software safety and security compliance?

Dr. Michael Back: Cetitec’s security architecture avoids wildcards, ensuring that only validated messages are processed. All messages are defined in a safety matrix with specific access rights, lengths, and parameters, and transmitted securely with firmware containers. This greatly reduces the risk of manipulation, as attacks would require a full compromise of the manufacturer’s update chain.

For functional safety, Cetitec complies with ISO 26262 standards. Certified out-of-context safety elements—like the Safetycore modules—enable ASIL-compliant integration of safety-critical functions, providing flexible solutions for advanced control systems.

Are there other software-related advantages?

Dr. Michael Back: A key benefit of Cetitec’s software is its OS-agnostic design. Post-build configurability allows developers to adjust system-critical parameters without recompiling the source code. Cetitec provides a developer-friendly toolchain that enables flexible configuration.

The software can run on bare metal, static systems, Linux, or POSIX, making it highly scalable. Middleware frameworks also help bridge communication between Linux, AUTOSAR, and bare-metal environments.

Dr. Back, can you provide a real-world example of how MicroSys hardware and Cetitec software work together?

Dr. Michael Back: In highly dynamic control applications, choosing the right sampling rate is crucial. Too low a rate leads to aliasing, distorting control algorithms and causing instability—especially in high-speed environments like drones, which can fly at 500 knots. Sensors must operate at high cutoff frequencies to calculate real-time flight corrections. The S32Z2’s DSP enables efficient real-time signal processing for data interpolation and noise filtering, significantly improving control precision.

Ms. Schindler, the first platform MicroSys adapted was NXP’s S32G CPU. How do the S32Z and S32G platforms complement each other?

Ina Schindler: As mentioned, we offer both S32Z2 and S32G platforms from NXP®. The S32G is ideal as a companion chip for specific applications. Customers benefit from a unified architecture using a single chip provider, simplifying system integration.

The S32G is optimized for communication and gateway functions, while the S32Z handles real-time control. Combined, they allow for efficient data aggregation, distribution, and processing—driven by the tight integration between MicroSys and Cetitec. In practice, we often see that a single chip can’t cover all use cases, especially as new sensors or functions are added. A redesign with added Z-controller integration allows all functional requirements to be implemented flexibly and efficiently.

About Cetitec

Cetitec, a Porsche company, is a leading software specialist in developing connectivity system solutions. Its scalable software products are key enablers for mobility solutions of globally significant automakers. With curiosity, passion, and dedication, Cetitec has been solving complex connectivity and communication challenges since 1999.

About MicroSys Electronics

Since 1975, MicroSys Electronics has been developing and manufacturing embedded systems. As a Gold Partner of NXP®, the company focuses on integrating NXP’s S32 Automotive, Layerscape, and QorIQ processor technology. Based in Sauerlach near Munich, MicroSys specializes in System-on-Module (SoM) designs, ranging from application-ready SoMs to custom carrier boards and complete systems. These rugged and long-term available designs are primarily used in safety-critical industries requiring compliance with standards like IEC61508, EN50155 (rail), DO-160 (aerospace), ISO 13849 (machinery), ISO 10218 (robotics), IEC 61131-6 (control), IEC 61800-5-2 (drives), IEC 60601 (medical), IEC 61513 (nuclear), and IEC 61511 (process industry). MicroSys works closely with customers in all these sectors to ensure compliance with relevant standards.